Reinforcing Steel Bar with Good Mechanical Properties

Reinforcing steel bar is produced by hot rolling process with subsequent superficial hardening by heat treatment. Commonly, it is supplied in length of 6 m to 12 m. According to the surface treatment, it can be classified into plain bar and deformed bar. Plain bar is often used in situations where the reinforcing steel bar is expected to slide, such as in highway pavements or in segmental bridges. Compared with the plain bar, the deformed bar has a wide range of applications from reinforced concrete slabs to prefabricated beams, columns, cages and precast products. As we all know, concrete is a material that is very strong in compression, but virtually without strength in tension. In order to make up this imbalance in a concrete slab's behavior, reinforcing steel bar is cast into it to take the tensile loads away. Therefore, reinforcing steel bar is widely used in the construction industry.

Plain bar is made of low carbon steel and common alloy steel, mainly used for supporting bars of reinforced concrete and prestressed concrete structures.

Deformed bar with ribs can well combine with concrete. Generally ribs on the surface can be classified into herringbone shape, spiral shape, and crescent shape.

Plain bar is hot rolled bar, commonly used in civil engineering construction. And its packing includes two types: 6.5 mm - 12 mm bars usually rolled into coils; 12 mm - 40 mm bars usually cut into straight strips, then packed in bundles.

Deformed bar with ribs can well combine with concrete. Generally it is used in reinforced concrete slabs, prefabricated beams, columns, cages, precast products, etc.

Specification

- Diameter: 6 mm - 40 mm.

- Material: HRB335, HRB400, HRB400E, HRB500, G460B, G500B, GR60.

- Steel bar length: 6 m - 12 m.

- Standards: AISI, ASTM, BS, DIN, GB, JIS, etc.

- Packing details: in bundles or as your requirement.

| Item | Diameter (mm) | Cross Sectional Area (mm2) | Theoretical Weight (kg/m) | Weight of 12m Bar (kg) | A Ton Contains 12m Bars (pcs) |

|---|---|---|---|---|---|

| RSB-6 | 6 | 28.27 | 0.222 | 2.664 | 375.38 |

| RSB-8 | 8 | 50.27 | 0.395 | 4.74 | 210.97 |

| RSB-10 | 10 | 78.54 | 0.617 | 7.404 | 135.06 |

| RSB-12 | 12 | 113.1 | 0.888 | 10.656 | 93.84 |

| RSB-14 | 14 | 153.9 | 1.21 | 14.52 | 68.87 |

| RSB-16 | 16 | 201.1 | 1.58 | 18.96 | 52.74 |

| RSB-18 | 18 | 254.5 | 2 | 24 | 41.67 |

| RSB-20 | 20 | 314.2 | 2.47 | 29.64 | 33.74 |

| RSB-22 | 22 | 380.1 | 2.98 | 35.76 | 27.96 |

| RSB-25 | 25 | 490.9 | 3.85 | 46.2 | 21.65 |

| RSB-28 | 28 | 615.8 | 4.83 | 57.96 | 17.25 |

| RSB-32 | 32 | 804.2 | 6.31 | 75.72 | 13.21 |

| RSB-36 | 36 | 1018 | 7.99 | 98.88 | 10.43 |

| RSB-40 | 40 | 1257 | 9.87 | 118.44 | 8.44 |

Features

- High fatigue resistance.

- Minimum crack width.

- High bonding strength.

- Desired flexibility.

Applications

Reinforcing steel bars are mainly used in construction industry, manufacture of anchor bolts, masonry structures and so on.

- Building structures: slab-on-ground, walls, structural floor slabs, stairs, roof construction.

- Road structures: road pavements, walk-able surfaces, segmental bridges.

- Other uses: box culverts, drainage structures, small concrete canals or pads, repair, etc.

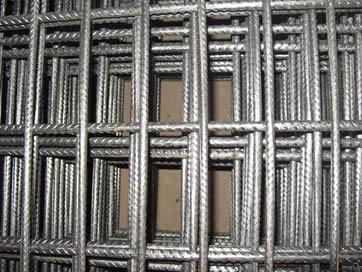

Reinforcing steel bar can be made into steel mesh. Reinforcing steel mesh is widely used in coal mine, high-rising commercial buildings, airport runway, highways, tunnels, bridges, concrete pipes, dam foundation, wharves, warehouse, etc.

Reinforcing steel bar for bridge structures: it can save steel material and decrease construction and maintenance fees; what's more, because of prestressing force, the bridge structures are more safe and reliable.